For instance, juniper bark makes an excellent lightweight but sturdy quiver that provides more arrow protection than skin. But bark cylinders too narrow to reach one’s hand into do offer a creative challenge for getting them laced up! Flat-bottomed, free-standing containers can be made from one or two panels laced up to form the sides, with a third circular or oval slab laced onto one end to form the bottom.

Various lids for containers can also be created. There is evidence that red cedar bark baskets were occasionally sealed with pitch along all seams and holes and used as water containers and/or for hot stone boiling, although I’ve not yet tried this with juniper (there’s always more to do!).

A successful experiment I did recently try was substituting frame-stretched and dried elk rawhide for bark. The only significant construction difference I found was that the rawhide folded easier when scored on the outside.

A simpler style of folded basket I’ve seen pictured of cedar but not juniper bark eliminates the elliptical bottom and is simply scored in a straight line across the midpoint of the panel. Then, proceeding as normal, the sides are bent up, edge margins overlapped, drilled and laced and finally the rim piece affixed. Because this style has a V-shaped bottom produced by the straight-line fold, it holds less, but capacity can be increased by forming the mouth to a circular shape, gently spreading the panel sides apart to their limit and propping these both in place until dry.

Whether you are surrounded by tulip poplars in the East, live in the land of western junipers, or are somewhere in-between or beyond, where other trees may work just as well, one-piece folded and laced bark containers are fun to make and multi-functional for the modern abo. So, when spring rolls around, your blood’s flowing, the sap’s up, the weather turns hot and you experience uncontrollable urges to begin peeling things off, embark on a new kind of basket project—bet you can’t make just one!

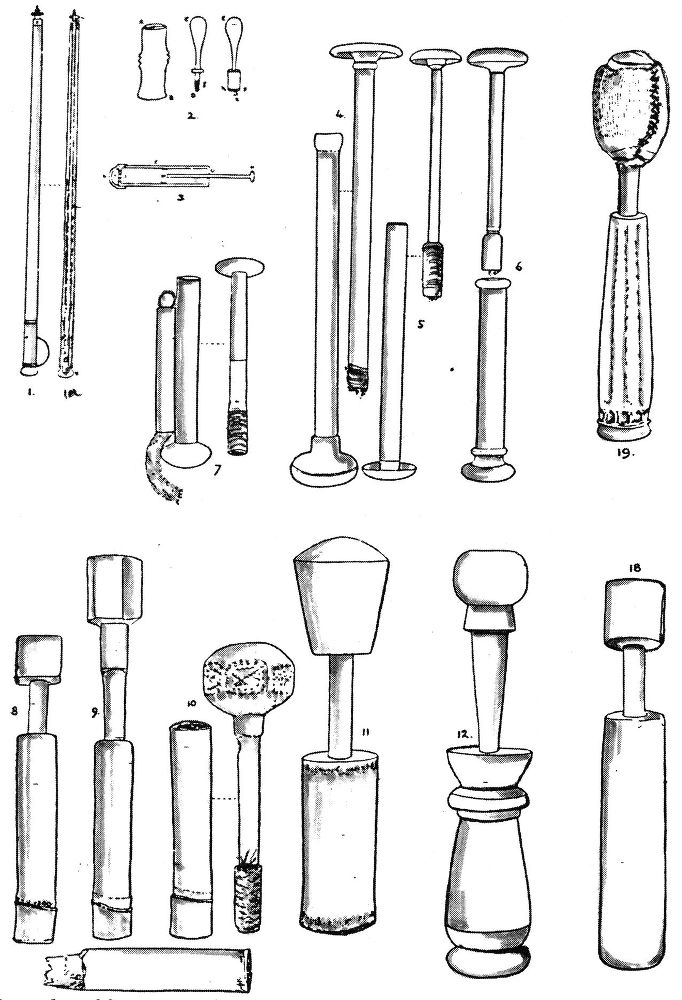

Examples of fire pistons from Europe (1-7) and farther India (8-12, 18-19). Illustrations reprinted from Henry Balfour, M.A., “The Fire Piston” Annual Smithsonian Report, 1907.

Richard Jamison with Mel Deweese

The Remarkable Fire Piston

Learning to operate the fire piston is the easy part. Ideally, you would “practice” with a proven model, experiment with different materials, then go on to make your own. Unfortunately, there are so few working models available it seems that we are destined to start from the other end of the spectrum and first experiment, then practice.

I first read about the fire piston in Bushcraft by Peter Graves. Being a visual person, the reference didn’t hold much significance for me until I saw one demonstrated at the Woodsmoke Rendezvous. But when I did see it, I immediately knew how the Australian aborigines must have felt when they saw a Bic lighter for the first time. I was seeing this incredible discovery, a primitive fire machine, and I was absolutely fascinated. That was in 1979. I thought about the fire piston quite a lot after that—I wanted one and tried to find out where I could get my own.

It was Mel Deweese, then a senior survival instructor for the U.S. Navy S.E.R.E. program, who first showed me the fire piston. His came from an isolated village in the Philippines. He and his group landed in the jungle in a helicopter and the local people came out to see what all the commotion was about. They were wearing loin cloths and carrying bows and arrows. Out of the corner of his eye, Mel saw one of the natives push something in and pop it out, and light his cigarette with it. He couldn’t communicate because of the language barrier, but he managed to trade the fellow a Zippo lighter and two pieces of Hubba Bubba for the fire piston. They were both happy!

I doubt Mel understood the significance of his remarkable new “cigarette lighter” at the time, and after hearing his story, it was pretty unlikely that I was going to just go out and buy one-so I decided to make my own. I studied Mel’s fire piston carefully and tried to duplicate it.

A fire piston is a remarkable device. It operates on the same principle as the diesel combustion engine. There are three absolute essentials necessary for producing heat in this manner: 1) A cylinder with accurate bore, usually closed at one end; 2) a piston accurately fitting the cylinder; 3) tinder which is very quickly flammable.

As air is forced into the shaft by a rod or “piston” the velocity condenses the air and creates heat. The intense heat ignites a small ball of tinder which is packed into a concave depression at the end of the piston. The piston is quickly withdrawn, and the glowing tinder (coal) is picked out of the depression and dropped into a tinder bundle, then blown into flame. It sounds very simple, but there are a number of elements that have to be “Just right” to get it to work.

I started with ash (Fraxinus) as the material for both the cylinder and the piston and drilled the shaft with a power drill. It didn’t work. I tried different types of tinder, thinking that would resolve the problem. I used juniper bark, dogbane fibers, cattail down, and cotton with no success. Next I tried maple with no more luck. I tried wrapping the piston with more string to form a tighter gasket, nothing. I used more, then less “grease” on the piston, but that didn’t work either. (I should mention that there is no “degree” of success with the fire piston, either it works or it doesn’t.)

At a loss, I turned to my knowledge of auto mechanics to follow the example of the diesel engine, and made some adjustments to my experimental model. Still no success.

My son Scott, who is an aeronautical engineer, says you can always tell an engineer because they tear a project apart and put it back together before they read the instructions. I’m not an engineer, but I am a mechanic of sorts, and I am persistent. So I resolved to “read the instruction manual,” so to speak, and do my research.

I checked the local library. Nothing. There were no references to a fire piston at all. I checked other sources and asked people I thought should know. Still nothing. So I did the logical thing and shelved the project.

Then, as fate will have it, in 1980, I was doing research for the movie Windwalker and happened to run across a 1907 report on the subject of fire pistons. Not only were examples shown in the form of illustrations, but the history of it’s discovery and evolution were cited. As a result of the references listed, I was able to research additional writings and reports. I was back on track.

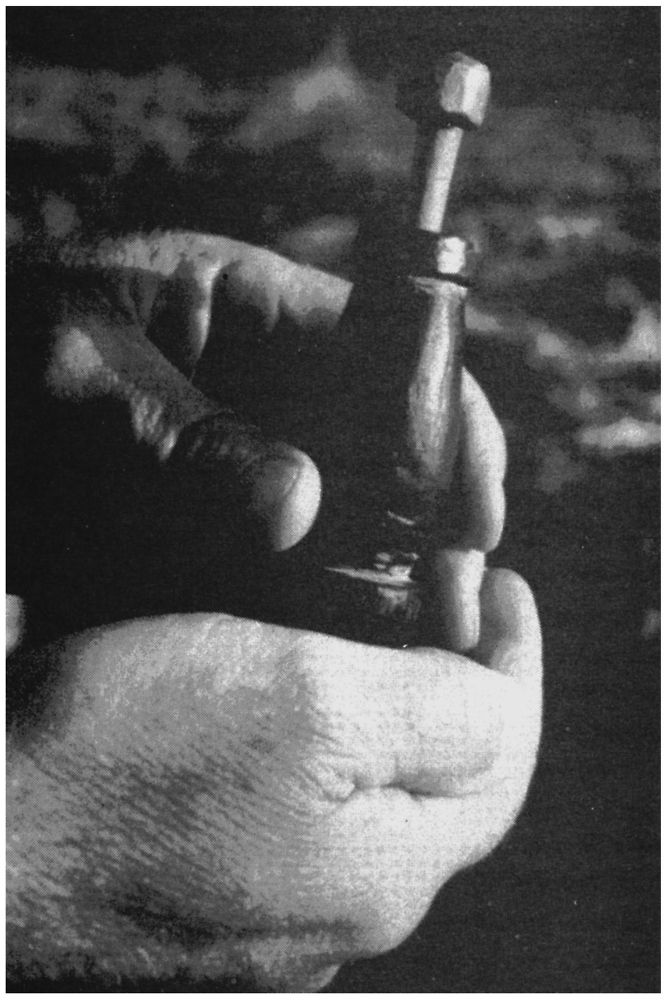

Fire piston cylinder made from buffalo horn with wooden piston. From Mel Deweese collection (Photo by Richard Jamison).

I will abbreviate some of the information contained in those reports for you here. I apologize for the lengthy reference to early accounts and descriptions, but I feel it is important to turn to a time when the fire piston was in practical use for examples. I think these references are valuable to anyone who intends to build a working model of the fire piston. The reports also present some interesting ethnological questions that illustrate academic thinking around the turn of the century and which, to some degree, still exists today.

Discovery

According to various reports, the fire piston appeared almost simultaneously in two very different parts of the world—Europe and Asia. We will begin by taking a look at the discovery of the fire piston in Europe.